About Us

Rooted in Sri Lanka. Trusted Worldwide.

We specialize in producing and exporting premium-grade True Ceylon Cinnamon — grown exclusively in the southern coastal regions of Sri Lanka. As a division of a globally certified agricultural group, our focus is on organic cultivation, ethical sourcing, and complete transparency from farm to shipment.

Our name reflects our mission: delivering Genuine, GI-Certified Cinnamon that honours nature, supports local farming communities, and meets the highest international standards.

Our Legacy

A Tradition of Excellence in Every Stick

Our cinnamon story began decades ago, with a commitment to cultivating spices using regenerative and organic farming techniques. Today, we serve clients across the globe — from premium food brands and herbal supplement companies to natural product retailers and importers.

Over 25 years of cinnamon cultivation and processing experience

Vertically integrated operations: from farm to container

In-house quality control, certification handling, and traceability

Why Choose Us?

You can trust us because we combine:

Decades of hands-on expertise

Full global certifications (USDA, EU, JAS, Fairtrade, FSSC 22000, GI-certified)

Customizable packaging options for private label partners

Export-friendly documentation and logistics

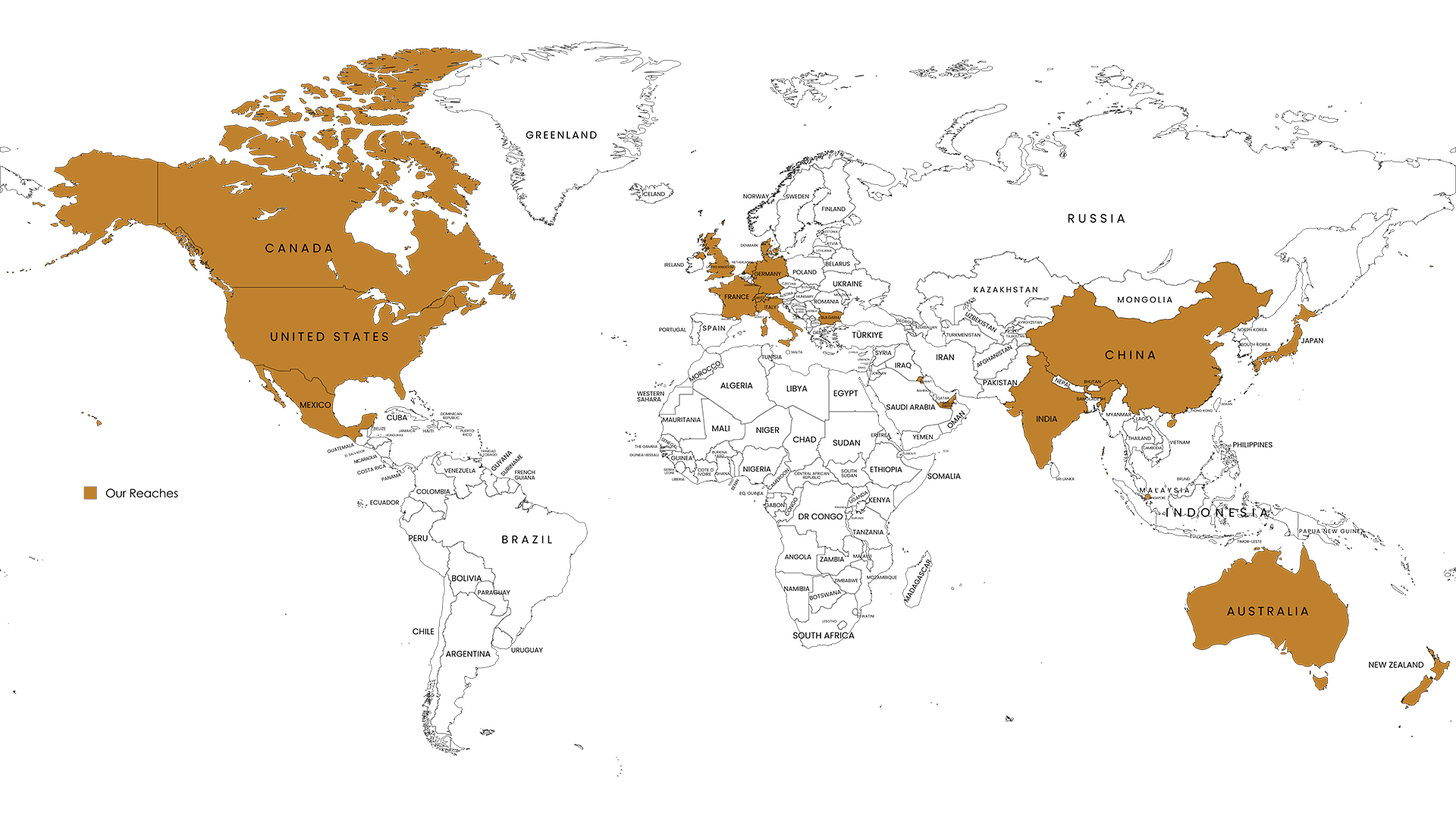

We export to 40+ countries across 7 continents

Our Certifications

Joint Agri Products Ceylon (Private) Limited

Let's Bring Real Ceylon Cinnamon to Your Market

Whether you’re sourcing for food, wellness, or health products — we offer tailored cinnamon solutions for your brand. Start a partnership that puts authenticity and quality first.